Cold feed barrels Manufacturers

We believe in: Innovation is our soul and spirit. Quality is our life. Customer need is our God for Cold feed barrels,Barrels, With our rules of " organization track record, partner trust and mutual benefit", welcome all of you to function together , improve jointly.

Cold feed barrels, Welcome any of your inquiries and concerns for our products. We look forward to establishing a long-term business relationship with you in the near future. Contact us today. We are the first business partner to suit your needs!

Hot Products

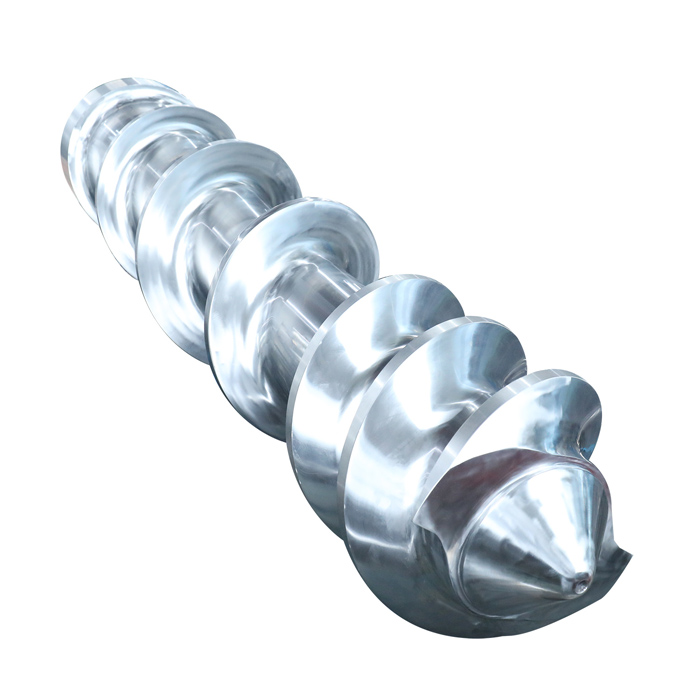

Pin Rubber Extrusion Screw and Barrel

Pin Rubber Extrusion Screw and Barrel is mainly used for shaping extrusions of various of rubber pipe, tread,cable and others from rubber compounds at room temperature. EJS produces PIN barrel extruder screw and barrel for leading players in the rubber field.Hot Feed Rubber Extrusion Screw And Barrel

Rubber industry only had Hot Feed Extruders until 1950’s. Hot Feed Extruders(HFE) extrude rubber compounds at reduced temperatures. EJS produces hot feed rubber extrusion screw and barrel, with rich experiences working with leading players in the rubber field in different countries.Welcome to buy Hot Feed Rubber Extrusion Screw And Barrel from us.Twin Screw Barrel

Twin screw barrels are critical and most complex to produce, EJS was born from twin screw barrels in 1992, we have the technical know-how to provide twin screw barrel made in design or sample.Parallel Twin Cylinder

EJS INDUSTRY is a top producer of parallel twin cylinders in our “Town of Screws”.Welcome to buy Parallel Twin Cylinder from us.Pelletizer Twin Screw Barrel

Pelletizer twin screw barrel is used on twin-screw pelletizer extruder, a high-speed, co-rotating extruder to best satisfy the compounding needs. EJS pelletizer twin screw barrel is reliable in most demanding jobs such as extrusion of plastics with rich fillers, reinforcing fibers, or with heat sensitive additives, shear sensitive additives.Extrusion Blow Moulding Screw Barrel

In extrusion blow molding (EBM), plastic is melted and extruded into a hollow tube (a parison). ... Air is then blown into the parison, inflating it into the shape of the hollow bottle, container, or part. After the plastic has cooled sufficiently, the mold is opened and the part is ejected. At EJS, we produce extrusion blow moulding screw barrel for extrusion blow moulding machines, with size small and big, in nitriding or bimetallic treatment.